china metal slurry pump manufacturers

Latest articles

Why would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

china metal slurry pump manufacturers...

china metal slurry pump manufacturers 【china metal slurry pump manufacturers】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

china metal slurry pump manufacturers...

china metal slurry pump manufacturers 【china metal slurry pump manufacturers】

Read MoreSlurry Pump

china metal slurry pump manufacturers...

china metal slurry pump manufacturers 【china metal slurry pump manufacturers】

Read MoreIn a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

china metal slurry pump manufacturers...

china metal slurry pump manufacturers 【china metal slurry pump manufacturers】

Read MoreAs the slurry is collected at the bottom of the tower, more rubber lined pumps are required to transfer the slurry to storage tanks, tailings ponds, waste treatment facilities or filter presses. Depending on the type of FGD process, other pump models are available for slurry discharge, pre-scrubber recovery and catch basin applications.

china metal slurry pump manufacturers...

china metal slurry pump manufacturers 【china metal slurry pump manufacturers】

Read MoreSites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

china metal slurry pump manufacturers...

china metal slurry pump manufacturers 【china metal slurry pump manufacturers】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

china metal slurry pump manufacturers...

china metal slurry pump manufacturers 【china metal slurry pump manufacturers】

Read MoreSlurry pump considerations

china metal slurry pump manufacturers...

china metal slurry pump manufacturers 【china metal slurry pump manufacturers】

Read MoreSlurry Pump Impeller Type

china metal slurry pump manufacturers...

china metal slurry pump manufacturers 【china metal slurry pump manufacturers】

Read MoreUnder ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

china metal slurry pump manufacturers...

china metal slurry pump manufacturers 【china metal slurry pump manufacturers】

Read More

Popular articles

- To reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

- On the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

- There is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

- Monitoring

- >TL FGD Pump

- Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

Latest articles

-

Types of slurry pump installation.

-

Determine the perfect combination of slow pumping (to reduce wear) and fast pumping to prevent solids from settling and clogging.

-

What is a dredging pump?

-

If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

-

Pumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

-

If you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

Links

- Another benefit of the 50mm electrical tape is its color options. Available in a range of colors, including black, red, blue, green, and yellow, this tape can be used for color-coding purposes or for simply adding a pop of color to your electrical work. This makes it easy to keep track of different wires or components, simplifying the troubleshooting process down the line.

- PVC insulation tape, often referred to as electrical tape, is a versatile and indispensable material in the world of electrical wiring and maintenance. Its significance lies in its ability to provide insulation and protection to electrical wires, cables, and components, thereby ensuring safety and efficiency.

- Yellow tape, commonly referred to as caution tape or warning tape, is a ubiquitous feature in areas that require heightened vigilance. Its presence on floors, walls, or even across doorways is a visual cue, alerting individuals to potential hazards or designated zones. It acts as a physical and psychological barrier, guiding foot traffic and preventing unintended intrusion into restricted or unsafe areas.

- Blue insulation tape is a versatile tool that is commonly used in various industries for its ability to provide protection and insulation for wires and cables. This type of tape is made from high-quality vinyl material that is durable, flexible, and easy to work with.

What is electrical tape?

How to Choose Silicone Rubber Tape and Rubber Repair Tape?

In addition to providing protection, car harness tape also helps to organize and secure the wiring harnesses in your vehicle. By neatly wrapping the tape around the harnesses, you can prevent them from getting tangled or damaged during routine maintenance or repairs.

- In conclusion, 50mm wide insulation tape is more than just a simple adhesive strip; it's a powerful tool in electrical safety and maintenance. Its broad width, combined with its durable properties, makes it an essential element in any toolbox, whether for professional electricians or DIY enthusiasts. Always remember, proper insulation is not only about convenience but also about preventing potential hazards, and the 50mm wide insulation tape stands as a reliable safeguard in this regard.

No special tools or skills are required – simply cut, apply, and press firmly for an instant fix No special tools or skills are required – simply cut, apply, and press firmly for an instant fix

No special tools or skills are required – simply cut, apply, and press firmly for an instant fix No special tools or skills are required – simply cut, apply, and press firmly for an instant fix flex seal tape blue. It's a DIYer's dream, offering a quick and convenient solution to emergencies, saving time and effort that would otherwise be spent on extensive repairs.

flex seal tape blue. It's a DIYer's dream, offering a quick and convenient solution to emergencies, saving time and effort that would otherwise be spent on extensive repairs.Lighting and A/V Electrical Control Boxes

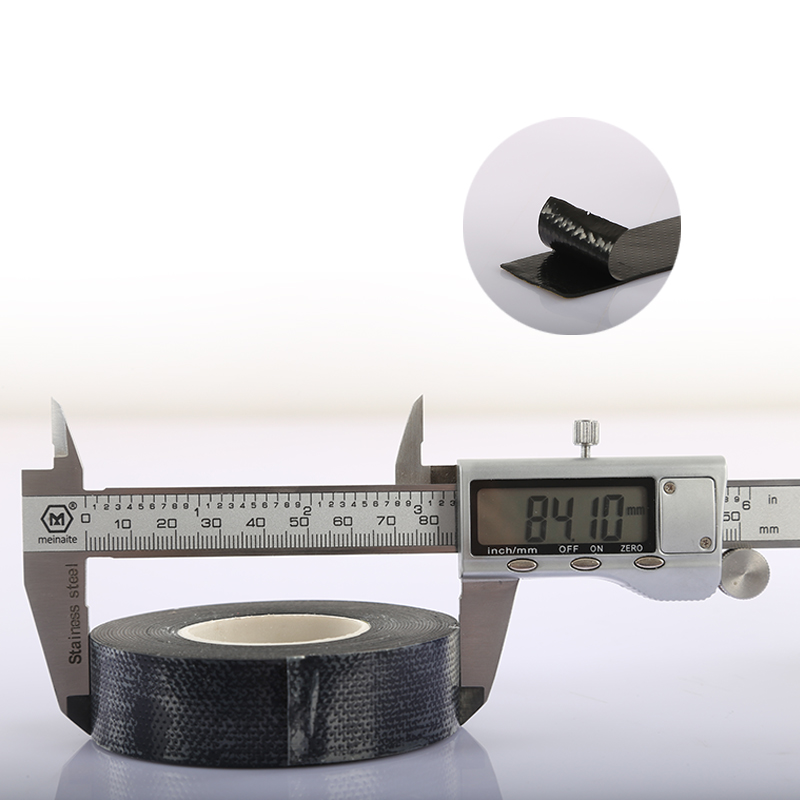

Width: Available in 19mm and 25mm

industrial floor marking tape. It requires minimal downtime, making it ideal for busy facilities. The tape can be easily removed without leaving residue, allowing for quick changes or updates when needed.

industrial floor marking tape. It requires minimal downtime, making it ideal for busy facilities. The tape can be easily removed without leaving residue, allowing for quick changes or updates when needed.Split bolt connection. Protection of a split bolt connection begins with installing the connector and wrapping it with two layers of varnished cambric tape. Next, wrap the splice with four half-lapped layers of rubber or rubber mastic tape. Complete the job by over-wrapping with at least two half-lapped layers of premium vinyl electrical tape.

Overlap Layers: For added strength, consider overlapping multiple layers of tape. This is particularly important in high-pressure or high-temperature applications.

Most types of electrical tape have a maximum operating temperature between 80°C and 130°C.

Electrical wiring and phasing tasks call for a specific type of tape – electrical tape – in order to safely get the job done. But what exactly is it that makes electrical tapes so different from duct tapes, polyethylene film tapes, and others?

First, decide on the material you will use to build the encapsulation. While selecting the material, you should consider numerous factors.